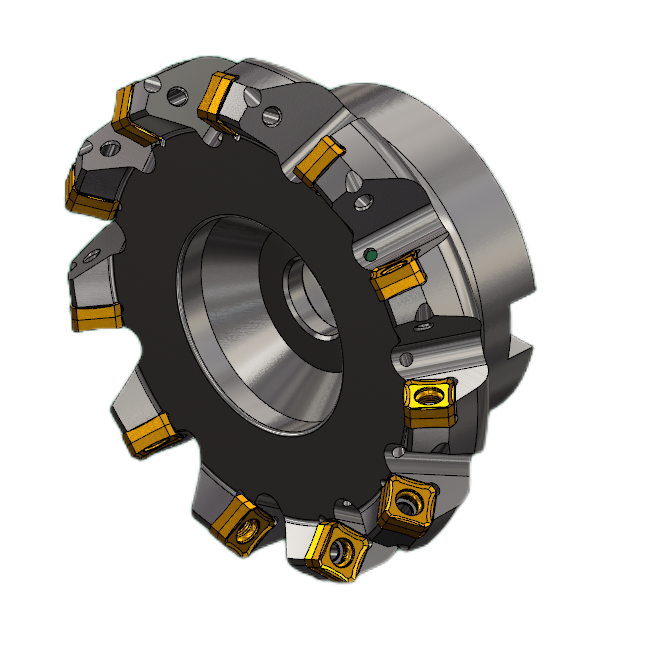

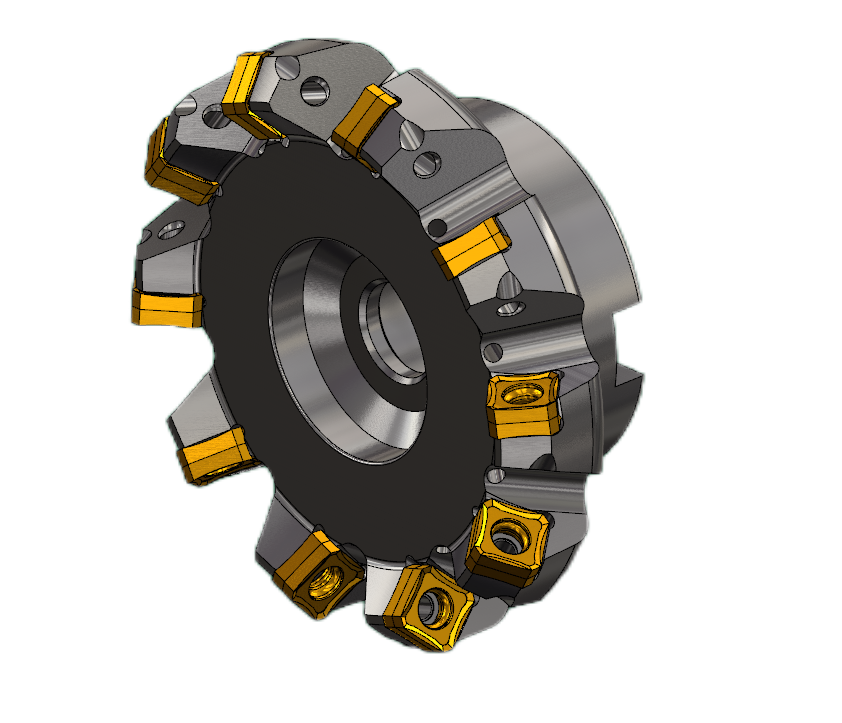

The 45°SN1205 water outlet cutter is a common milling tool. The following are its uses and benefits

Release time:

2025-05-10

Author:

Source:

The 45°SN1205 water outlet cutter is a common milling tool. The following are its uses and benefits:

The 45°SN1205 water outlet cutter is a common milling tool. The following are its uses and benefits:

use

- Large-area planar processing: suitable for large-area planar milling operations on large-area workpieces such as flat plates, boxes, bases, etc. of cast iron, steel or aluminum alloy, and can achieve efficient and stable large-area material removal.

- Angle surface processing: Due to the angle characteristics of the insert contact with the workpiece, it is suitable for milling the surface of the workpiece with a certain slope, such as the inclined surfaces, guide rails, sliders on machine parts that require precise angle control.

- Cavity Milling: In mold manufacturing, it can be used to mill the complex three-dimensional shapes of the injection mold or die-cast mold cavity, such as ribs, ribs, chamfers and other characteristics, which can effectively avoid interference and improve the surface quality of the mold.

- Thin-walled parts processing: In the aviation, automobile and other industries, it can be used to process thin-walled structural parts such as wing spars and engine housing. With smaller cutting force and lower cutting noise, the workpiece deformation and vibration are reduced and the precision machining requirements are ensured.

benefit

- Light cutting: Usually, the cutting edge of the blade has a large front angle and curved edge structure, and the double negative structure of the tool body is light and the chip removal is smooth.

- Good processing quality: The blade is finely polished and comes with polishing. With a cutting angle of 45 degrees, you can obtain high surface quality during processing.

- Good heat dissipation: The water outlet hole design can quickly cool the tool and workpiece through internal cooling, take away the cutting heat, reduce tool wear, and improve the tool service life. It also helps improve the quality of the processing surface and prevent the workpiece from deforming due to heat.

- High stability: The tool adopts a cutting force balance design, and the angle of 45 degrees makes the cutting force distribution more reasonable, the machining stability is good, and the vibration resistance is excellent.

- Fast feeding speed: Dynamic inclined surface design achieves low resistance and low vibration sense, which can effectively improve the processing feeding speed and thus improve processing efficiency.

Key words:

Water outlet cutter plate

Latest News

East end of Nan Huan Road, Pingyuan County, Dezhou City, Shandong Province, China

WhatsApp: