1-Introduction to typical face milling cutter products

Release time:

2025-03-06

Author:

Source:

face milling cutter, end mill cutter, inxable milling cutter, face mill

1-Introduction to typical face milling cutter products

(一)Sanco Milling Cutter

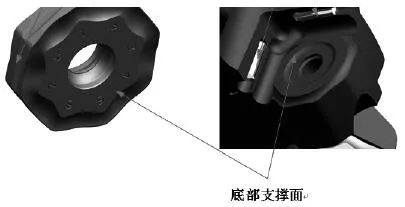

1. Double OctomillTM Sanco Double-Sided King Milling Cutter Double OctomillTM Double-Sided King is a milling cutter that combines processing performance and economy. Each blade has 16 cutting edges and a unique high-precision blade positioning system (see Figure 4-25), which provides consistent high-quality processing results based on hardened positioning pins. It can be used as both a roughing tool and a finishing tool. It is mainly used in the processing of cast iron, steel and stainless steel parts.

Double OctomillTM

Product Features:

1) Diameter range φ80~φ315mm.

2) Fixed blade seat, adjustable blade seat, sparse teeth, dense teeth and super dense pitch.

3) Blade type: ON.09, ON.05.

4) Maximum effective rake angle 9°.

5) Maximum back cutting amount 6mm.

6) Runout is 10~20μm or less. The only patented insert seat design of SANGO.

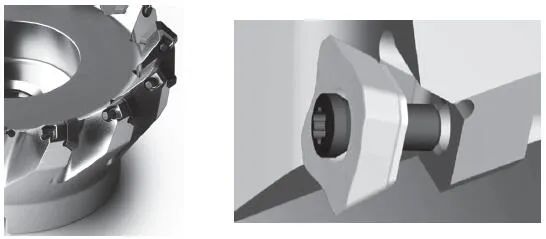

2. Sanco Quattromill® is the first choice for plane milling.

Quattromill®is a high-performance plane milling cutter with a 45° main rake angle using a square insert. This milling cutter cuts very lightly and can process all materials and is used in unstable working conditions.

Quattromill®

Product features:

1) There are steel cutter bodies and aluminum alloy cutter bodies.

2) Economical direct pressure inserts and ground high-precision inserts.

3) The inserts have a built-in wiper blade design.

4) The composite shim technology effectively protects the cutter body and reduces tool accessories.

5) The inserts are available in SE09, SE12, and SE15 types. The 09, 12, and 15 inserts can share the same cutter body by replacing the tool holder.

6) The unique locking screw design allows the insert edge to be easily replaced directly on the machine tool.

7) Design of sparse teeth, regular teeth, dense teeth and super dense teeth.

(二)Walter milling cutter

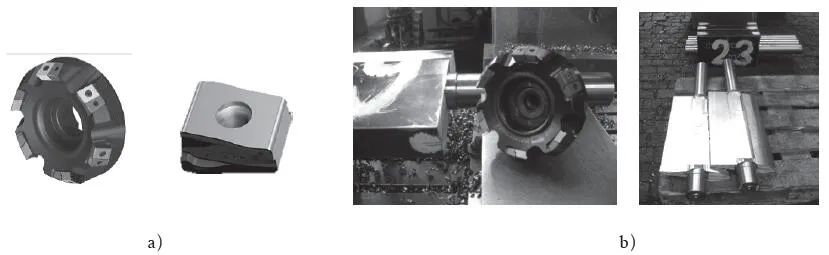

1. BLAXX heavy-duty cutting milling cutter M3016

(1)(1) Product introduction. Walter BLAXX heavy-duty cutting milling cutter M3016 also uses Tiger·tec® Silver technology. The blade materials include WKP25S and WKP35S with CVD chemical coating and WKK25S and WSP45S with PVD physical coating, which are suitable for processing steel and cast iron. The stable tangential indexable blade provides extremely high process reliability, and the stopper can effectively protect the cutter body when the blade breaks.

M3016

Each indexable insert has 4 cutting edges, so M3016 can reduce tool costs while increasing metal removal rate. The positive groove shape ensures light cutting, and the rounded insert achieves maximum stability. This new tool is particularly suitable for rough machining of workpieces with large cutting volumes and achieves the highest metal removal rate on all steel and cast iron materials.

(2)Example

1) Part: Kaplan turbine blade.

2) Workpiece material: 1.4313X3CrNiMo13-4 + VT 78*.

3) Machine tool: TOS Kurim, 15kW, DIN 69871 SK50.

4) Milling cutter: M3016-125-B40-06-16, κr = 60°.

5) Milling insert: LNMX201012R-F57T WSP45S.

6) Milling cutter diameter: φ125mm, number of teeth: z=6.

7) Application: rough milling plane.

8) Cutting parameters: ap=3.5~15mm, vc=135-175m/min, fz=0.23~0.34mm/z, vf= 355~900m/min, ae=75~112.5mm.

9) Processing effect: blade life 60min, completed 2 workpieces. The processing efficiency is increased by 30% and the processing life is increased by 100% compared with the previous tool.

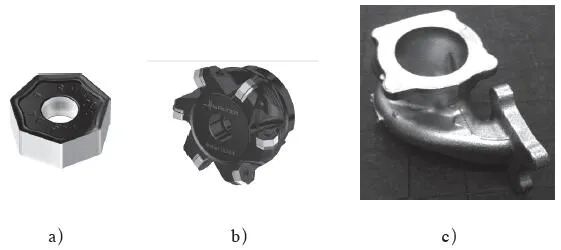

2. Walter BLAXX (Black Blade) Heptagonal Blade Milling Cutter M3024

(1) Product introduction. Tiger·tec® Silver insert technology increases metal removal rates and reduces tool costs.

The new Walter BLAXX M3024 heptagonal insert milling cutter (see Figure 4-28) can achieve high metal removal rates even on less powerful machines thanks to its positive and light cutting characteristics. Each indexable insert has 14 cutting edges, which reduces tool costs. Carbide shims provide optimal support and ensure maximum safety at high feeds; at the same time, with stable negative indexable inserts, high process reliability is easily achieved.

Walter BLAXX heptagonal insert milling cutter is equipped with CVD chemically coated Tiger·tec® Silver insert materials (WKP25S and WKP35S), suitable for processing steel and cast iron materials. In addition, there are 3 PVD physical coating materials (WSM35S, WKK25S and WSP45S) for machining steel, cast iron and stainless steel. This tool is recommended for machining workpieces such as turbochargers or turbine blades.

(2) Application examples

1) Part: turbocharger housing.

2) Workpiece material: G-X 40 CrNiSi 25 12 (1.4837).

3) Machine tool: SW BA600-dual spindle machine tool, tool holder: HSK-63A.

4) Milling cutter: M3024-063-B22-06-04.

5) Milling insert: XNMU0705ANN-F57 WSP45S.

6) Milling cutter diameter: φ63mm, number of teeth: z=6.

7) Application: milling plane, milling flange surface.

8) Cutting parameters: ap=3.5mm, vc=169m/min, fz=0.25mm/z, ae=40mm.

9) Processing effect: blade life 60 pieces. Compared with the previous tool, the processing efficiency is increased by 20%, and the tool life is increased by 50%.

Key words:

face milling cutter,end mill cutter,inxable milling cutter,face mill

Next

Next:

Latest News

East end of Nan Huan Road, Pingyuan County, Dezhou City, Shandong Province, China

WhatsApp: